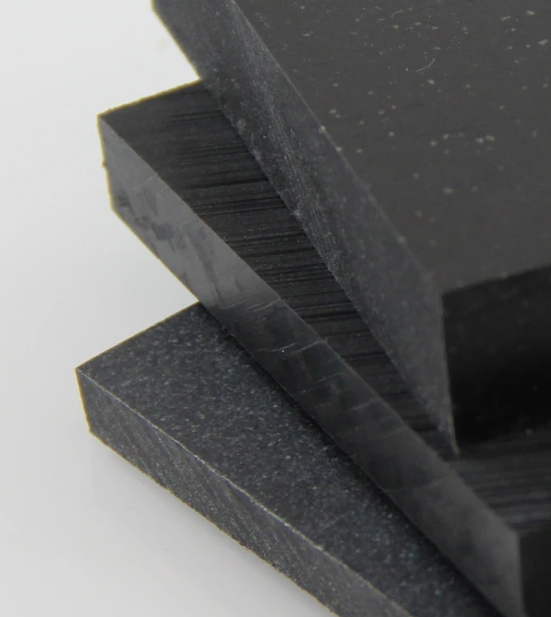

Polycarbonate Sheeting

Clear, colored / Select / 48" x 96" / Cut-To-Size

Sold by: Precision Plastics

Need a Quote?

Property: Polycarbonate

Shear Strength: 10,000 psi

Yield Tensile Strength: 9,500 psi

Other Colors: Multi-color, White, Black

Call (855) 508-3396

Or

Click To Get A Quote Today

Call To Place OrderOr

Click To Get A Quote Today

Material Overview

Polycarbonate sheeting is a type of thermoplastic material known for its exceptional strength, impact resistance, optical clarity, and versatility. It is made from polycarbonate resin, which is a polymer that can be molded and formed when heated and returns to a solid state when cooled. Polycarbonate sheets offer several advantages that make them popular in various industries and applications.

Here are some key characteristics and benefits of polycarbonate sheeting:

STRENGTH AND IMPACT RESISTANT -Polycarbonate sheets are highly durable and have an excellent strength-to-weight ratio, making them virtually unbreakable. They can withstand high impacts without cracking or shattering, making them a safer alternative to glass.

OPTICAL CLARITY - Polycarbonate sheets have excellent transparency, allowing high light transmission. They offer optical clarity similar to glass, making them suitable for applications where visibility is important, such as windows, skylights, and displays.

LIGHTWEIGHT - Polycarbonate sheets are lightweight compared to glass, which makes them easier to handle, transport, and install. This property is particularly advantageous in applications where weight reduction is important, such as in transportation and construction.

- Weatherability

- Versatility

- Flame Resistance

- Chemical Resistance

- Sound Insulation

Polycarbonate sheeting finds applications in various industries, including construction, architecture, automotive, electronics, signage, agriculture, and medical equipment. Its combination of strength, impact resistance, optical clarity, and weatherability make it a reliable and versatile material for a wide range of demanding applications.

Specifications

We offer polycarbonate sheeting is available in various sizes to accommodate your different project requirements. Polycarbonate sheets are typically manufactured in standard dimensions that include thickness, width, and length. Give us a call to place your order at (855) 508-3396

The information contained herein includes typical values intended for reference and comparison purposes only. This information should NOT be used as a basis for design specifications or quality control. Field testing is recommended for any application.

*Chem is an abbreviation for chemically affixed with glues, chemicals, or adhesives.

**Mech is an abbreviation for mechanically affixed bonding.

Applications

Polycarbonate is a versatile material that finds a wide range of applications across various industries. Some common applications of polycarbonate include:

- Construction and Architecture: Polycarbonate sheets are used in construction for applications such as transparent roofing, skylights, canopies, and architectural panels. Their durability, impact resistance, and light transmission properties make them ideal for these applications.

- Automotive: Polycarbonate is used in automotive applications such as headlamp lenses, interior trim, instrument panels, and sunroof panels. Its lightweight nature, impact resistance, and optical clarity make it suitable for these demanding applications.

- Electrical and Electronics: Polycarbonate is employed in electrical enclosures, switchgear components, connectors, and insulators due to its excellent electrical insulation properties and flame resistance.

- Safety and Security: Polycarbonate sheets are used in safety equipment such as face shields, safety goggles, riot shields, and security glazing. Their high impact resistance and strength make them effective protective barriers.

- Signage and Displays: Polycarbonate is commonly used for signage, displays, lightboxes, and point-of-purchase displays. Its transparency, impact resistance, and ease of fabrication allow for creative designs and effective visual communication.

- Agriculture: Polycarbonate sheets are widely used in greenhouse structures due to their high light transmission, durability, and ability to provide insulation. They help create an optimal growing environment for plants.

- Medical Equipment: Polycarbonate is used in medical equipment and devices, including incubators, blood oxygenators, surgical instruments, and protective barriers. Its biocompatibility, impact resistance, and sterilization capabilities make it suitable for medical applications.

- Aerospace: Polycarbonate finds applications in aerospace components such as aircraft windows, cabin interiors, and cockpit displays. Its lightweight nature and impact resistance are beneficial in the aerospace industry.

- Sports and Recreation: Polycarbonate is used in sports equipment like helmet visors, protective gear, safety goggles, and ski goggles. Its impact resistance and optical clarity make it suitable for these applications.

- Transparent Security Enclosures: Polycarbonate is used in security applications such as transparent barriers, protective enclosures, and ATM machine covers. Its impact resistance, clarity, and durability provide both safety and visibility.