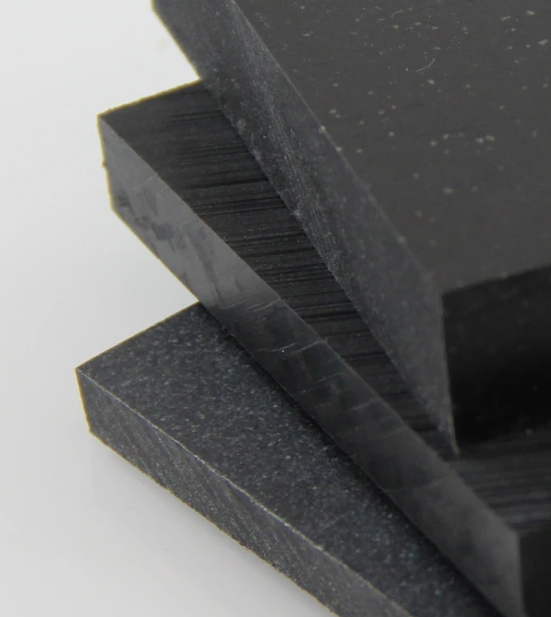

ABS - Acrylonitrile Butadiene Styrene

Black, white / Select / 48" x 96" / Cut-To-Size / Textured

Sold by: Precision Plastics

Need a Quote?

Property: Acrylonitrile Butadiene Styrene - (ABS)

Density: 0.0376 lbs./in. 3| 64.9 lbs./ft.3

Yield Tensile Strength: 6000

Other Colors: White, Black

Call (855) 508-3396

Or

Click To Get A Quote Today

Call To Place OrderOr

Click To Get A Quote Today

Material Overview

ABS sheeting is known for its exceptional strength, impact resistance, and durability, making it suitable for a wide range of applications. It is commonly used in industries such as automotive, construction, electronics, and signage. ABS sheeting is lightweight and easy to handle, making it convenient for fabrication and installation. Its excellent mechanical properties allow it to withstand harsh environments and extreme temperatures.

Additionally, ABS sheeting is known for its good chemical resistance and low moisture absorption, further enhancing its durability. Its versatility and reliability have made ABS sheeting a popular choice for various applications where a combination of strength, impact resistance, and aesthetic appeal is required.

GOOD CHEMICAL RESISTANCE - ABS (Acrylonitrile Butadiene Styrene) is known to have excellent resistance to many common chemicals, including alcohols, diluted acids, alkalis, and hydrocarbons. It can withstand moderate exposure to oils, greases, and certain solvents.

EXCEPTIONAL STRENGTH - ABS sheets possess good impact resistance, allowing them to withstand moderate impacts and mechanical stresses without breaking or cracking easily. This characteristic makes ABS a popular choice in applications where durability and resilience are important, such as automotive parts, protective equipment, and consumer goods.

DURABILITY - ABS exhibits good resistance to weathering and UV radiation. It can withstand prolonged exposure to sunlight without significant degradation or discoloration, making it suitable for outdoor applications. ABS has good dimensional stability, meaning it maintains its shape and dimensions even under changing temperatures and humidity conditions. This stability is essential for applications where precise fit and long-term performance are required. While ABS may not be the most robust material available, it offers a good balance of durability, impact resistance, and dimensional stability, making it a reliable choice for many everyday applications.

- Good chemical resistance

- Exceptional strength

- Highly durable

- Easily bonded with adhesives

- Easy to machine and thermoform

- Low cost

- California residents see Prop 65 Warnings

Specifications

ABS sheeting is available in various sizes to accommodate your different project requirements. We commonly manufactured ABS in standard dimensions that include thickness, width, and length. Give us a call to place your order at

| Sizing | |

|---|---|

| 48" x 120" | ¼” |

| 48" x 120" | ⅜” |

| 48" x 120" | ½” |

| 48" x 120" | ¾” |

| 48" x 120" | 1” |

| ABS Sheeting | - |

|---|---|

| Density (lbs./in.3 | lbs./ft.3) | 0.0376 | 64.9 |

| Tensile Yield Strength (psi) | 6000 |

| Tensile Modulus | 310 ksi |

| Flexural Modulus | 340 ksi |

| Flexural Yield Strength | 10000 psi |

| Izod Impact, Unnotched | 7.5 ft-lb/in |

| Falling Dart Impact | 12 ft-lb -40°F |

| Falling Dart Impact | 33 ft-lb 73°F |

| Izod Impact, Unnotched @ -40°C | 2.5 ft-lb/in |

| CTE, linear 68°F | 50 µin/in-°F |

| Deflection Temperature at 1.8 MPa (264 psi) | 198 °F |

| Gloss | 90 % |

The information contained herein includes typical values intended for reference and comparison purposes only. This information should NOT be used as a basis for design specifications or quality control. Field testing is recommended for any application.

*Chem is an abbreviation for chemically affixed with glues, chemicals, or adhesives.

**Mech is an abbreviation for mechanically affixed bonding.

CNC Machinery + Different Sheet Sizes = Anything You Want

Don’t need a full sheet? No problem. We can cut pieces to your specifications. And you can pick up the same day.

Confirm your specs. Wait a few minutes. Then walk out with your pieces. It’s really that simple.

Applications

ABS (Acrylonitrile Butadiene Styrene) sheeting is widely used in a variety of applications across different industries due to its desirable properties. Some common applications of ABS sheeting include:

- Automotive: ABS is used for interior and exterior parts in automobiles, including dashboards, instrument panels, door panels, trim, and grilles.

- Electronics and Appliances: ABS is utilized for housing and structural components in electronic devices, such as computer keyboards, computer monitors, printers, and household appliances.

- Construction: ABS sheets are employed in construction for wall cladding, decorative panels, signage, and architectural modeling.

- Consumer Goods: ABS is found in various consumer goods, including luggage, cases, toys, sporting equipment, and furniture components.

- Safety Equipment: ABS is used for protective gear like helmets, face shields, safety goggles, and body armor due to its impact resistance.

- Point-of-Purchase Displays: ABS sheets are utilized in point-of-purchase displays, retail fixtures, and signage due to their versatility and ability to be easily fabricated and formed.

- Medical and Healthcare: ABS is employed in medical equipment and devices, such as medical instrument trays, housings, and enclosures, due to its sterilizability and resistance to chemicals.

- Educational and Artistic Applications: ABS sheets are commonly used in educational models, prototypes, art projects, and crafts due to their ease of use, affordability, and versatility.

- Marine Applications: ABS sheets find use in marine applications for instrument panels, cabinetry, and interior components due to their resistance to water and durability.

- Packaging: ABS sheets are utilized in packaging applications, including clamshell packaging, blister packs, and protective cases for products.

Call Us Today At (855) 508-3396

Or

Submit Your Info To Be Contacted

Receive your personalized quote in less than 24 hours.

Call Today!